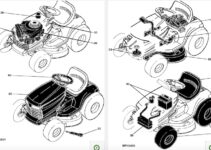

The John Deere Z425 mower is a residential mower built to help mow large estate lawns properly. This mower isn’t designed to function as a commercial mower. It’s a zero-turn mower that is very fast and offers exceptional performance than most other tractor-style mowers.

Generally, the mower offers good value for money, and as such, it’s highly converted. You’re in the right place if you desire more information about this mower.

In this guide, we’ll reveal the diagram of the John Deere Z425 parts and expound on the crucial components amidst other necessary information.

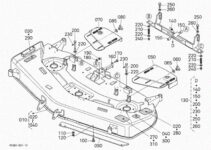

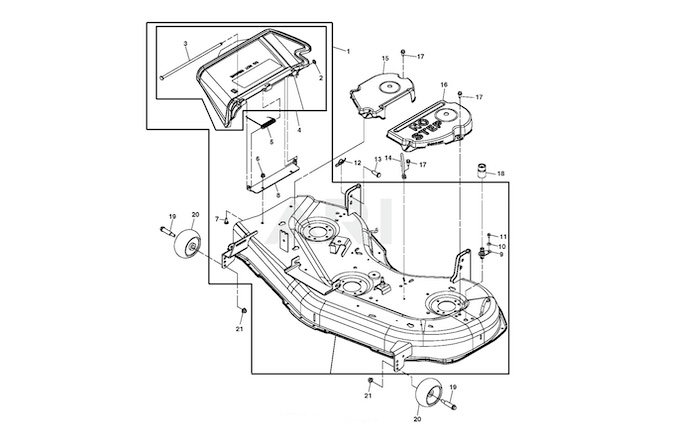

John Deere Z425 Parts Diagram

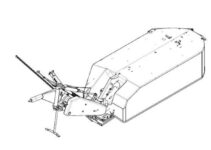

The John Deere Z425 mower is a 48-inch deck perfect for many people. It’s a zero-turn mower, which might be challenging to use on new turns when you corner, but it’s exceptional on level ground.

The components are rigid and durable. They are built with some of the best materials that boast immense resistance to lawn harshness. Here’s a diagram showing the different components of the John Deere Z424 mower:

- Mower Deck

- Push Nut

- Pin Fastener

- Chute

- Spring

- Lock Nut

- Bolt

- Hinge

- Port Plate

- Washer

- Screw

- Cotter Pin

- Pin Fastener

- Guide

- Shield

- Shield

- Screw

- Quick Coupler

- Screw

- Anti-Scalp Wheel

- Lock Nut

- Mower Deck

- Lock Nut

John Deere Z425 Parts Explained

While people enjoy this mower’s performance, most need help understanding the different parts of the mower and how they operate. It’s crucial to understand the functions of each component and how they work together to offer efficiency.

These parts share some connections, and some are paramount to the overall functionality of the machine. They include Blades, Carburetor, Air Cleaner, Crank Shaft, and Oil Seal.

Mower Blades

The blades are the most crucial component of a lawn mower because they are in charge of effectively and precisely cutting the grass.

The blade first raises the grass before cutting it. After being chopped into smaller pieces, clippings are sucked inside the deck. The small clippings are blown out by air pressure created by the innermost curve of the blade, where they feed the soil.

Since they must be capable of withstanding rapid encounters with a wide range of objects in addition to grass, they are typically made of sturdy metals. The components used and the blades’ dimensions, thickness, and designs differ depending on the manufacturer.

Carburetor

In lawnmowers, the engine generates motion by burning fuel which produces heat energy and is harnessed to provide movement. But, the fuel must be mixed with air to generate substantial heat. This part is where the carburetors come in.

A carburetor is a component that supplies fuel to the combustion chamber. The Carburetors’ job is to create this mix. It mixes the fuel and air in proportion to reduce fuel consumption and maximize power.

Several variables, such as how long the engine has been working, the terrain you are driving over, and your speed, are taken into account by carburetors when adjusting the mixture of air and fuel. The two carburetors used are the semi-injection carburetor and the standard carburetor. The fuel pump inside a semi-injected carburetor is distinctive.

Air cleaner

An air cleaner is a lawnmower that filters outside air before it enters the combustion chamber. The carburetor section contains this air filter.

The air filter is the lawn mower’s first line of defense against debris and dirt present during the mowing session. It keeps dirt, debris, leaves, small stones, and other debris particles from accessing the engine through the carburetor when it is in good condition and functioning correctly. Because the air cleaner is a foam filter, it’s always simple to clean.

Crank Shaft

The primary shaft of the lawn mower is the crankshaft. It is the pivot point of the entire lawn mower part’s round of work. It connects the pistons and the flywheel and is essential for the engine to start. It helps transform a piston’s reciprocating motion into a rotational motion.

Internal combustion engines frequently use it to carry out such an operation. Connecting rods are attached to crankshafts through a series of cranks and crankpins.

The flywheel, which also drives the fan belt and the transmission, is cranked in a circular motion by the crankshaft using the upward and downward movement of the pistons.

Cast iron is typically used to make crankshafts. During the mechanism, molten metal is injected into a mold (Casting).

Some performance engines use forged steel crankshafts from the modern era. A block of steel is heated to a red-hot temperature to create it. After that, it is shaped with extremely high pressure.

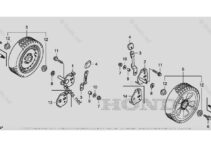

Flywheel

One of the most crucial parts of an automobile engine is the flywheel. It is a mechanical apparatus explicitly created to store rotational or kinetic energy.

A flywheel needs sufficient force to rotate on its axis because it is a heavy wheel. As a result of their moment of inertia, it resists changes in rotational speed. It keeps the crankshaft rotating between the engine’s power strokes by storing the momentum from combustion.