The fuel injection pump is a mechanical device that conveys the fuel into the cylinders of automotive engines. It’s the heart of the diesel engine because it delivers power, thus maintaining a timing or rhythm that keeps the engine running efficiently.

The pump also regulates the fuel required to gain the needed power. Because of its significant importance, it’s crucial to learn about the injection pump to enhance the engine’s performance.

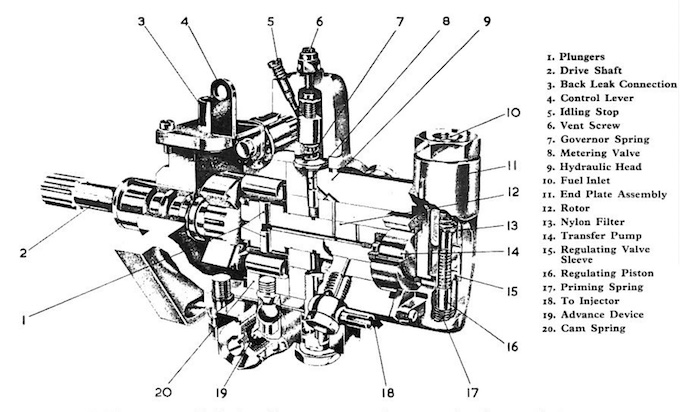

Alongside the diagram, this article will discuss the crucial components of the Lucas Cav Injection pump and explore its distinctive features.

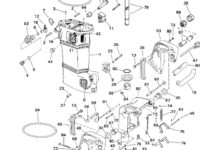

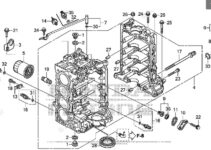

Lucas Cav Injection Pump Parts Diagram

The main function of the injection pump is to deliver fuel to the diesel engine’s cylinders. Thanks to the several components that make up the injection pump, it can perform this objective and impact the engine performance, noise characteristics, and emissions.

Below is the diagram showing the different components of the Lucas Cav injection pump:

Lucas Cav Injection Pump Parts Explained

When you check the injection pump diagram, you’ll realize that it comprises several components working together to achieve its objectives. The fuel injection pump is driven indirectly from the crankshaft by belts, gears, and chains.

Let’s explore the different parts and discuss their specific function in the system:

Plunger

The Plunger is a significant spare part of the injection pump system. It’s responsible for pumping fuel with very high pressure so the nozzle or injector can atomize it.

The function of the plunger, which moves upward and downward, is to assist in increasing the pressure of the diesel fuel before its atomization in the combustion chamber.

Delivery Valve

The Delivery Valve helps deliver fuel to the injectors above the EFI Pump. It’s a non-return valve that controls pressure waves inside the fuel line.

Governor Assembly

The shaft power drives the Governor Assembly and comprises a mechanical flyweight governor. The Governor, which houses the starting, control, and tensioning levers, can pivot within the mechanism’s housing.

It can freely rotate around the governor shaft because it is fixed inside the governor’s housing and attached to it. Because of centrifugal force, the flyweights rotate outward when they move, and this radial movement is transformed into a motion of the sliding sleeve.

Fuel Tank

The Fuel Tank serves as a reservoir and stores the fuel. It keeps the temperature of the fuel below its flash point, serving as a means of releasing heat from the engine.

To prevent fuel leaks, fuel tanks must be anti-corrosive and leakproof. Additionally, fuel tanks should withstand pressures higher than 30 kPa.

Fuel Supply Pump

The high-pressure pump receives fuel from the fuel tank via the fuel supply pump. The engine can power fuel supply pumps mechanically or electrically.

Its placement is unlimited thanks to electronic fuel supply pumps, including within the tank. Mechanical supply pumps can perform extra tasks in addition to their primary duties, such as a vacuum pump for brake boosters and a fuel pump.

Overflow Limitations

It is secured to the inside of the pump by screws that go into the governor cover. A tiny passageway enables a varying quantity of fuel to travel to the fuel tank. The resistance signifies the flow resistance that aids in maintaining pressure inside the injection pump.

Fuel Filter

The fuel filter is required for the engine to run correctly because fuel may contain contaminants. It may have one or more filtration stages. If it features two-stage filters, the primary filter is typically installed on the inlet side of the fuel transfer pump. The more significant contaminants are filtered out.

The secondary filter removes smaller particles that, if they reach the engine, could harm its components. The secondary filter must withstand intense pressure.

Timing Device

A fuel injection system’s primary function is to deliver diesel to an engine’s cylinders. Still, the timing and manner in which the fuel is delivered can affect an engine’s performance, sound, and emissions.

The timing mechanism of the injection pump controls when fuel will be injected into the cylinder and when the piston will reach BTDC. Additionally, it modifies the start of delivery based on the load and the pump speed.

Fuel Injector

The fuel injector is an electronic valve. Depending on the characteristics of the mixture in a diesel engine, fuel injectors atomize the fuel into tiny droplets. They also inject it into the designated combustion chamber after that.

It supplies this valve with pressurized fuel and opens in response to a command. It has a high rate of opening and closing in a split second. Additionally, fuel injectors are compatible with the spray properties of different styles of combustion chambers.

Electromagnetic Shutoff Valve

The electromagnetic shutoff valve is also known as the engine stop solenoid. It is designed to disrupt the fuel supply to the engine to force it to stop. It serves as a means of cutting fuel supply to the pump. The solenoid is usually energized before the engine starts, opening the fuel flow to the engine. However, the solenoid power is removed when the machine stops, closing the fuel line.