The Northstar pressure washer is a top-quality machine that has proven reliable. The device is built for dependability, long life, and consumer-top performance.

The machine is intended to produce a high-pressure water spray. You can also incorporate cleaning chemicals into a low-pressure water spray.

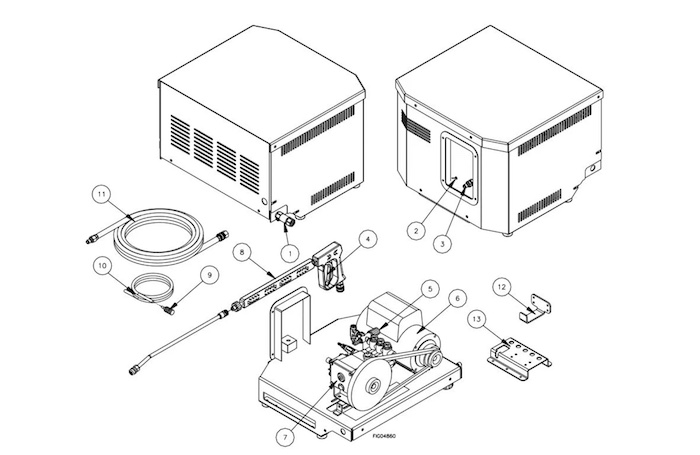

To fully understand the machine, you’ll need to read the manual. To save you time, we’ll provide the diagram of the Northstar pressure washer and discuss the function of the different components.

Northstar Pressure Washer Parts Diagram

The more time you take to understand the machine components, the better you’ll maintain it, enjoy its operation and improve its efficiency. As one of the industry leaders, the machine has exceptional performance to offer consumers, which you can want only through a critical understanding of the machine.

- Inlet Filter

- On/Off Switch

- High-Pressure Outlet

- Trigger

- Unloader

- Electric Motor

- Pump

- Spray Gun

- Chemical Strainer

- Chemical Hose

- Pressure Hose

- Hose Hook

- Nozzle Bracket

Northstar Pressure Washer Parts Explained

The Northstar pressure washer produces hot or cold water, high-pressure spray, and steam spray. The diagram above reveals that the Northstar pressure washer comprises some integral components crucial to its functionality. Each of these components significantly affects how the pressure washer functions.

Below is the role of each component in the overall function of the pressure washer:

Water Inlet

The water inlet is a hose that links the pressure washer and the primary water source. A filter is usually attached to it to prevent the entry of external particles or debris from accessing the pressure washer and harming the machine.

If the debris accesses the washer, it can ruin the entire machine and cause complications. It’s also harmful because the pressure will catapult the waste out, potentially causing harm to humans or nearby objects.

Electric Motor

The electric motor is also known as the gas engine. It’s another significant part of the pressure washer that powers the engine. It powers the water pump to pull in the water and detergent and mix them.

High-Pressure Hose

The high-pressure hose is the tube that extends from the pressure washer to the cleaning object you are using. It helps distribute pressurized water to the target while the water inlet supplies the pump with water. The high-pressure water must be sturdy and durable enough to handle the pressure of the water pumping out of it.

Generally, standard tubing can’t work and can be harmful to use. It will not survive the high pressure of the water passing through it. Hence, it’s essential to use the hose and attachments that come with the machine. A high-pressure hose is usually reinforced with a wire mesh and more than two layers of high-density plastics.

Numerous industrial and commercial settings make use of high-pressure water hoses. They help generate pressurized water for specific manufacturing procedures or other cleaning operations. They are made of premium rubber and require maintenance to last a long time. Without caution, the rubber will become brittle and fracture when under pressure.

Water Pump

This is where a pressure washer gets its power, and it’s often regarded as the heart of the machine. It resembles a hand-operated groundwater pump in some ways.

Still, the gas engine or electric motor drives it at high speed rather than your hand. Water from the faucet is sucked in when the engine draws the pump in one direction.

However, water shoots out in a high-pressure jet when it pushes the pump in the opposite direction. An average water flow through a pump is about 4-8 liters or 1-2 gallons per minute.

Trigger Guns

The trigger gun is another crucial component of the pressure washer. The part keeps the pressurized water from flowing out of the gun nozzle without control.

This component is built with a ball bearing tightly fit to the outflow valve, apart when the lance is mounted. When the water is built, it helps increase the seal pressure between the valve and the ball bearing, enabling no leak during the operation.

A pin pushes the ball away when the gun’s trigger is pulled, allowing the water to shoot out the nozzle via the lance and the valve. The motor is also turned on when the trigger is squeezed, increasing water pressure and guaranteeing evenly steady flow. Immediately the trigger is pulled, and the ball bearing is pushed back into place by a spring.

Unloader Valve

The pressure washer unloader valve is a safety switch for the machine. Its function is simple: direct the water flow through a by-pass when the trigger gun is depressed.

It cycles the pressurized water into this by-pass from the outlet side of the pump to the water tank or the inlet. It is designed to react to an increase or change in water flow. It can also function as an adjuster to modify the machine’s pressure.